News & Events

The EC7BW18-ECRT/EDRT : All-in-1 Power Solution for Railway Application

16

Apr

Apr 16, 2021

According to the railway standard EN 50155, the common nominal input voltages, 24Vdc, 36Vdc, 48Vdc, 72Vdc, 96Vdc and 110Vdc are all used to distribute the needed power throughout the whole system. In EN 50155 standard, the fluctuation voltage range also needs to be considered. (See Table 1). CINCON Railway solution provides the ultra-wide input range products covering the fluctuation voltage range. Today we are introducing the EC7BW18-ECRT/EDRT which is the chassis-mount series and built-in with the EMC solution. There are 2 chassis mount types: ECRT (Enclosed Chassis mount + Railway Turnkey) and EDRT (Enclosed chassis mount + Din rail + Railway Turnkey).

|

Table 1: EN50155 Input voltage range |

|||

| Nominal Input Voltage (Vin) |

Continuous Voltage Range (0.7*Vin-1.25*Vin) |

Fluctuation Voltage Range |

|

| 0.6*Vin (0.1S) | 1.4*Vin (1S) | ||

| 24V | 16.8V - 30V | 14.4V | 33.6V |

| 36V | 25.2V - 45V | 21.6V | 50.4V |

| 48V | 33.6V - 60V | 28.8V | 67.2V |

| 72V | 50.4V - 90V | 43.2V | 100.8V |

| 96V | 67.2V - 120V | 57.6V | 134.4V |

| 110V | 77V - 137.5V | 66V | 154V |

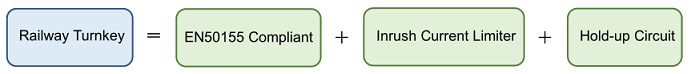

Definition of CINCON Railway Turnkey

Based on Cincon’s definition, a railway turnkey should include the following elements:

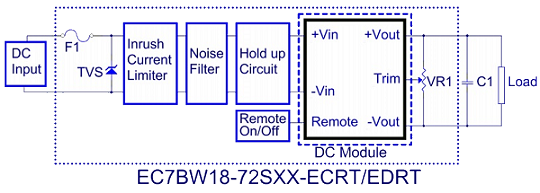

You may see the clear picture from the following layout. It shows the structure of EC7BW18-ECRT/EDRT. The series is compliant to EN 50155, and built in with inrush current limiter, hold-up circuit, and EMI solution as the railway turnkey power solution.

Compliant to EN50155

EN 50155 is the railway standard in Europe. In order to be EN 50155 compliant, a device must pass the requirements of test items including the temperature, humidity, vibration, shock, and electrical tests (See Table 2). To simulate the harsh environment for railway operation and check if the device would work properly, in most of major countries, the railway standard requirements are regulated based on EN 50155 standard. In CINCON railway solution, we have various products, including EC7BW18-ECRT/EDRT, compliant to EN 50155. The test items include visual inspection, performance test, power supply test, insulation test, low temperature storage test, low temperature start-up test, dry heat test, cyclic damp heat test, EMC test, vibration and shock test. In addition, Cincon has more products designed to meet EN 50155.

|

Table 2: EN50155 List of tests |

|||||

| Test | Type | Test | Type | ||

| 1 | Visual Inspection | M | 8 | Cyclic damp heat test | M |

| 2 | Performance test | M | 9 | Salt mist test | O |

| 3 | Power Supply test | M | 10 | Enclosure protection test (IP code) | O |

| 4 | Insulation test | M | 11 | EMC test | M |

| 5 | Low temperature storage test | O | 12 | Vibration and shock test | M |

| 6 | Low temperature start-up test | M | 13 | Equipment stress screening test | O |

| 7 | Dry heat test | M | 14 | Rapid temperature variation test | O |

|

Tests marked ‘M’ are mandatory. |

|||||

Inrush Current Limiter:

For railway DC-DC converters, adding a capacitor at the input side to increase the hold-up time is common. However, this transient characteristic of capacitor would cause the higher inrush current at the input side. The amount of the inrush current would be proportional to the input voltage and the capacitance value at the input side. If there is no action to restrain the inrush current, it will cause the voltage drop of the front-end power supply or trigger the over-current protection of the front-end power supply, leading to the consequence of no output of the DC-DC converter.

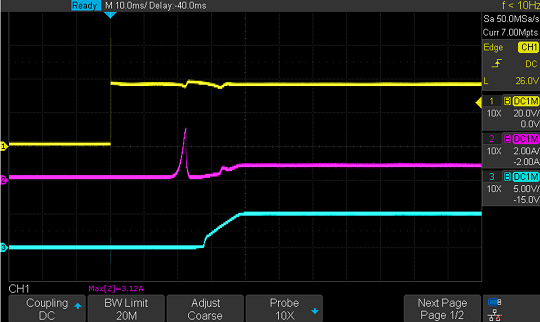

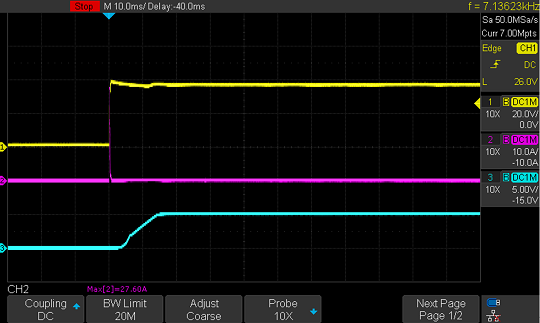

To overcome the problem, the EC7BW18-ECRT/EDRT is built-in with an active inrush current limiter which has better performance of efficiency loss and less impact by the ambient temperature while compared to a passive inrush current limiter. The photo (1) shows the inrush current of EC7BW18-72S05-ECRT with the active inrush current limiter is 3.12A at input voltage 36Vdc. By contrast, while the inrush current limiter is removed, the photo (2) shows the inrush current of EC7BW18-72S05-ECRT is 27.6A at input voltage 36Vdc. The inrush current is increased by 24.48A. Do not forget it is only at input voltage 36Vdc. When the input voltage is higher, the difference will be even lager.

| With Inrush Current Limiter | Without Inrush Current Limiter |

|

|

| CH1: Input Voltage | CH1: Input Voltage |

| CH2: Input Current | CH2: Input Current |

| CH3: Output Voltage | CH3: Output Voltage |

| photo (1) | photo (2) |

Hold-up Circuit

In a railway power supply system, it is common to see the fluctuation of the supplied voltage during distributing the electricity among generator, battery, and pantograph system within a short time. It may also cause a short period of open circuit or short circuit. Therefore, in the EN50155 power supply test, the Interruptions of voltage supply and the supply change-over are categorized into the following different classes:

Interruptions of voltage supply:

Class S1: No voltage interruption. No performance criterion is requested but the equipment shall continue to operate as specified after the voltage interruption.

Class S2: Interruption time 10ms. performance criterion A

Class S3: Interruption time 20ms. performance criterion A

Supply change-over:

Class C1: At 0.6*Vin during 100ms (without interruptions). Performance criterion A

Class C2: During a supply break of 30ms stating at Vin. Performance criterion B

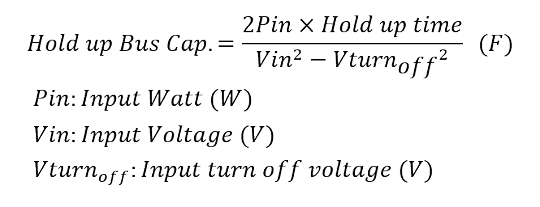

In order to have the device meet the requirements of S2, S3 and C2, the most common way is to add a capacitor at the input side (reason same as Inrush Current Limiter). The capacitance value could be determined by the formula below:

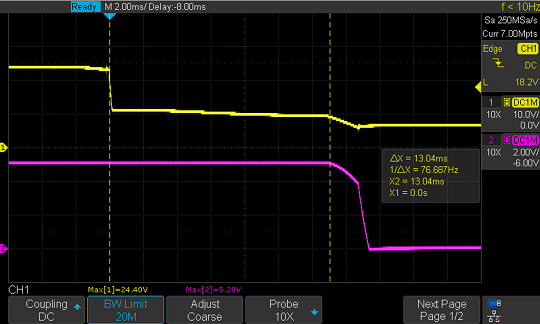

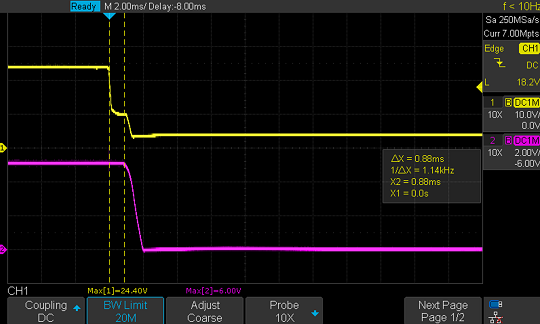

According to the formula, under the same hold-up time condition, when the input voltage is lower, the required capacitance value will be more. The EC7BW18-ECRT/EDRT has hold-up circuit including a capacitor which could meet S2, S3 and C2. (More details are in EC7BW18-ECRT/EDRT Datasheet & APPLICATION NOTE). The photo (3) shows the hold-up time of EC7BW18-72S05-ECRT with the hold-up circuit at input voltage 24Vdc. The hold-up time is 13ms. The photo (4) shows the hold-up time of EC7BW18-72S05-ECRT without the hold-up circuit at the same input voltage. The hold-up time decreases to 0.88ms.

| With Hold up Circuit | Without Hold up Circuit |

|

|

| CH1: Input Voltage | CH1: Input Voltage |

| CH2: Output Voltage | CH2: Output Voltage |

| photo (3) | photo (4) |

Conclusion

In this article, we show the definition of CINCON Railway Turnkey and the main concepts of the three elements. Our goal is to offer all-in-1 railway power solutions covering the needed components and circuit. In addition to being compliant to EN 50155, the capacitor, inrush current limiter, hold-up circuit for meeting S2, S3 and C2 requirements and the EMI solution are also covered. No need for extra component and circuit.

Besides offering a series of ultra-wide input ranges DC-DC converters for railway, Cincon provides Din-rail DC-DC modules suitable for distributed power architecture, telecom, battery-operated devices and industrial applications.

Product page: EC7BW18-ECRT/EDRT

Product Category: Ultra-wide input range DC-DC converters